iPhone NPI

2019-2020 | Technical Program Manager

iPhone Technical Operations | Apple

I was responsible for the final assembly, test, and packaging stages of the manufacturing process for iPhone NPI (new product introduction) builds. The iPhone 12 Pro Max involved unique challenges due to several design changes such as the flat band, 5G antennas, and new colors.

I led efforts to optimize laser etching while preserving cosmetic and functional reliability, button installation, cover glass assembly, and rear camera cosmetic cleanliness. With the onset of COVID-19, this product challenged our team to work together both in the overseas factory, in-office during factory hours, and remotely at home.

iphone 12 Pro Max

Laser Etch on PVD Coating

A substantial portion of my responsibility was managing the quality, legibility, and reliability of the laser markings on Europe-sold phones which are required to show the CE mark as well as WEEE compliance symbol.

Additionally, I led the qualification efforts, cost assessments, and machine allocation coordination with Quality, Supply Chain, and Automation teams.

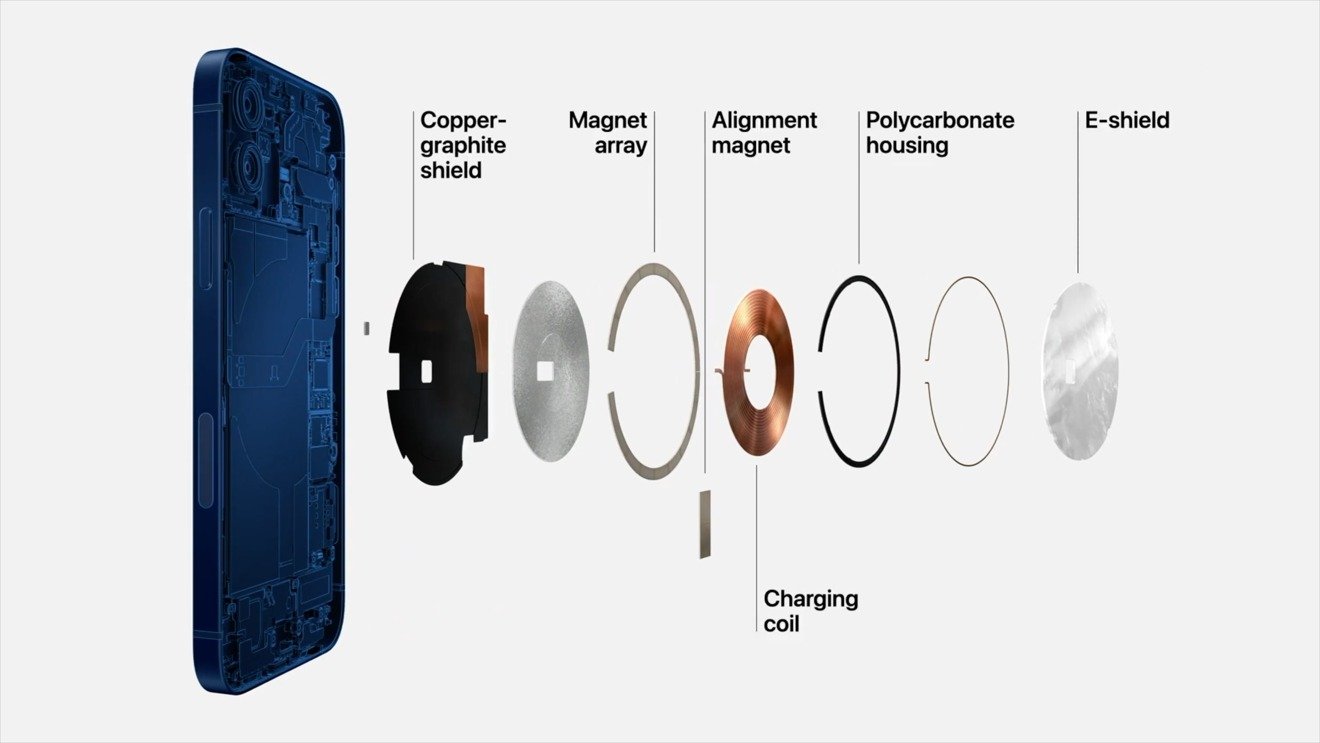

MagSafe Assembly

The MagSafe assembly differed from the prior iPhone model, thus our team worked to ensure the assembly did not result in component damage nor interfere with other critical components.

iPhone 11

Rear Camera Cosmetics

A huge challenge in making any physical product is cosmetic reliability. The iPhone 11 introduced several new anodized colors, some of which have a greater tendency for discoloration due to oils, lubricants, or other process-related fluids. I aligned with the design and quality teams to qualify a cleaning process.

Despite the qualification, it is still possible to have a few outliers, such as the image found on reddit below.